Vibratory Feeder

Production Capacity:1-105t/h

Feeding size: 125-250mm

Feed opening: 150×250-300×1300mm

Motor power: 5.5-55kw

Total weight: 0.8-15.6t

Production Capacity:1-105t/h

Feeding size: 125-250mm

Feed opening: 150×250-300×1300mm

Motor power: 5.5-55kw

Total weight: 0.8-15.6t

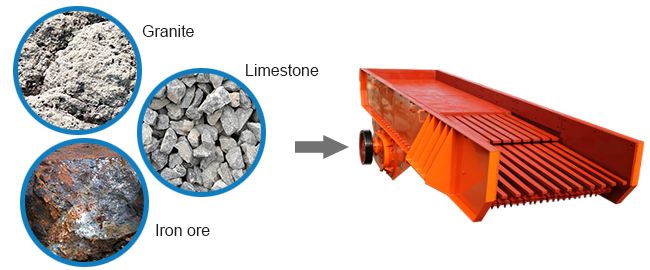

Vibrating feeder, also known as vibratory feeder, is used for transferring large-size materials and granular materials from hopper to receiving device uniformly, periodically and continuously in production line. Vibrating feeder can not only feed materials into crusher continuously and uniformly, but screen materials in stone production line. The vibrating feeder is equipped with crushing and screening equipment and widely used in many industries including metallurgy, coal mine, mineral dressing, building material and chemistry.

According to structure and usage, the vibrating feeder can be divided into four types: GZD type vibrating feeder, ZSW type vibrating feeder, GZZ type vibrating feeder and GZT type vibrating feeder.

GZD type vibrating feeder consists of vibrating frame, motor, spring, bearing and wear-resisting lining board, etc. The frame is forced to vibrate on the supporting spring, which will drive materials to achieve the purpose of feeding.

ZSW type vibrating feeder is composed of vibrating frame, spring, vibrator, electrical vibrating grid, motor, etc. The exciter is composed of two eccentric shafts and gears. The jogged gears create the vibration while the two eccentric shafts will be forced to rotate. Once power is supplied, the two eccentric shafts will start to rotate to produce huge power which forces the materials to slip forward and achieve the feeding purpose.

.jpg)

GZZ type vibrating feeder can remove the dirties and impurities of materials, control the feeding amount to match the process capacity, and transfer large-size materials uniformly, periodically and continuously in production line. It is the essential equipment with features of reliable structure, shock resistance and abrasive resistance, and it shall be used before the primary crushing.

| Model | Max. Feeding Size (mm) |

Processing Capacity (t/h) |

Motor Power (kw) |

Obliquity of material trough (°) |

Trough size (mm) |

Dimensions (L×W×H)(mm) |

| GZD-650×2300 | 300 | 80-100 | 1.2×2 | 10-20 | 650×2300 | 2300×1360×780 |

| GZD-750×2500 | 350 | 100-130 | 1.5×2 | 10-20 | 750×2500 | 2500×1460×780 |

| GZD-850×3000 | 400 | 120-150 | 3×2 | 10-20 | 850×3000 | 3110×1800×1600 |

| GZD-1000×3600 | 500 | 150-200 | 3.7×2 | 10-20 | 1000×3600 | 3850×1950×1630 |

| GZD-1100×3600 | 580 | 240-300 | 3.7×2 | 10-20 | 1100×3600 | 3600×2050×1660 |

| GZD-1300×3600 | 650 | 450-600 | 7.5×2 | 10-20 | 1300×3600 | 3900×2350×1750 |

| GZD-1500×3600 | 1050 | 450-1000 | 7.5×2 | 10-20 | 1500×3600 | 3900×2000×1750 |

| GZD-2000×3600 | 1200 | 550-1000 | 10×2 | 10-20 | 2000×3600 | 3600×2000×1750 |

| GZD-2500×5000 | 1500 | 650-1500 | 18×2 | 10-20 | 2500×5000 | 5000×2500×1800 |

| ZSW-380×95 | 500 | 100-180 | 11 | 0-10 | 3800×960 | 3920×1640×1320 |

| ZSW-490×110 | 630 | 150-400 | 15 | 0-10 | 4900×1100 | 4980×1830×1320 |

| ZSW-490×130 | 750 | 400-700 | 22 | 0-10 | 4900×1300 | 4980×2580×2083 |

| ZSW-600×130 | 750 | 400-700 | 22 | 0-10 | 6000×1300 | 6082×2580×2083 |

| ZSW-600×150 | 800 | 500-900 | 30 | 0-10 | 6000×1300 | 6086×2662×1912 |

| ZSW-600×180 | 900 | 700-1300 | 45 | 0-10 | 6000×1500 | 6310×3262×2230 |

| ZSW-600×200 | 1200 | 800-1500 | 55 | 0-10 | 6000×2000 | 6310×3462×2230 |

| Model | Max. Feeding Size (mm) |

Processing Capacity (t/h) |

| GZD-650×2300 | 300 | 80-100 |

| GZD-750×2500 | 350 | 100-130 |

| GZD-850×3000 | 400 | 120-150 |

| GZD-1000×3600 | 500 | 150-200 |

| GZD-1100×3600 | 580 | 240-300 |

| GZD-1300×3600 | 650 | 450-600 |

| GZD-1500×3600 | 1050 | 450-1000 |

| GZD-2000×3600 | 1200 | 550-1000 |

| GZD-2500×5000 | 1500 | 650-1500 |

| ZSW-380×95 | 500 | 100-180 |

| ZSW-490×110 | 630 | 150-400 |

| ZSW-490×130 | 750 | 400-700 |

| ZSW-600×130 | 750 | 400-700 |

| ZSW-600×150 | 800 | 500-900 |

| ZSW-600×180 | 800 | 700-1300 |

| ZSW-600×200 | 1200 | 800-1500 |