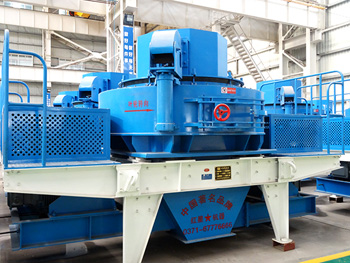

Sand Maker

Production Capacity:0.26–30 m3

Rotate speed: 200–530 r/min

Diameter: 240–850 mm

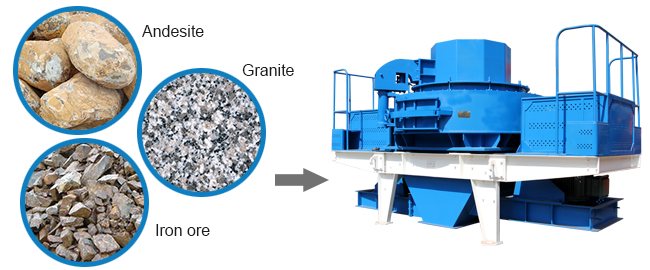

Applied material: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone.

Production Capacity:0.26–30 m3

Rotate speed: 200–530 r/min

Diameter: 240–850 mm

Applied material: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone.

Sand maker, also named sand making machine or artificial sand maker, is a suitable device in the sand making plant for crushing and reshaping soft materials or medium hard extremely hard materials and it is of particular higher efficiency and productivity in crushing dead-hard, extra-hard and corrosion-resistant materials such as, silicon carbide, carborundum, sintered bauxite, magnesia and so on.

.jpg)

.jpg)

.jpg)

.jpg)

The materials vertically fall into the high-speed rotating impeller from the upper part of the artificial sand maker, and impact and smash with each other under the centrifugal force. After impacting and crushing process of the artificial sand maker, the materials will form vortex between the impeller and the cabinet, and then be straightly discharged from the lower part, forming the closed-loop cycles. The screening device can be used to control the granularity of finished products.

.jpg)

VSI sand maker used in the sand making plant is the latest type of sand making machines which can save energy by over 50% than traditional sand maker. It is able to crush all kinds of rocks, gravels and river cobbles into building sand conforming to the desired granularity, the final sand is even in granularity and high in compression strength, so that it better conforms to the construction requirement of the sand making plant than natural sand and the sand produced by common hammer type sand maker and better improves the quality of the buildings. The VSI sand maker has many features such as reliable performance, reasonable design, convenient operation and high working efficiency.

.jpg)

| Model specification |

Max.feeding size (mm) |

Power (kw) |

Rotation speed of impeller (r/min) |

Capacity (t/h) |

Overall dimension (L×W×H) (mm) |

| HX-06 | 35 | 2P 37-55KW | 2000-3000 | 12-30 | 2500×1620×2600 |

| HX-07 | 45 | 4P 55-75KW | 1500-2500 | 25-55 | 2700×1760×2800 |

| HX-09 | 50 | 4P 110-150KW | 1200-2000 | 55-100 | 3900×2000×3070 |

| HX-10 | 60 | 4P 150-180KW | 1000-1700 | 100-160 | 4600×2350×3450 |

| Model specification |

Max.feeding size(mm) |

Capacity (t/h) |

| HX-06 | 35 | 12-30 |

| HX-07 | 45 | 25-55 |

| HX-09 | 50 | 55-100 |

| HX-10 | 60 | 100-160 |