Circular Vibrating Screen

Production Capacity:8-800m³/h

Vibrating power: 800-970r/min

Max. feeding size: 400mm

Screen size: 4-100mm

Motor power: 5.5-22×2kw

Production Capacity:8-800m³/h

Vibrating power: 800-970r/min

Max. feeding size: 400mm

Screen size: 4-100mm

Motor power: 5.5-22×2kw

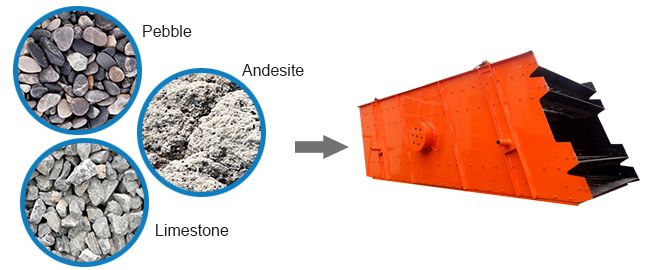

The circular vibrating screen is a vibrating screen with high efficiency and it advantages include stable structure, strong exciting force, high efficiency, low vibrating noise, durability, handy maintenance and safe operation. Circular vibrating screen has been widely used in mine, construction, transportation, energy, chemistry and other industries.

Circular vibrating screen is mainly composed of screen box, exciter, suspension (or support) system, electric motors and other components. The V-belt of the electric motor can drive the vibration exciter spindle to rotate, and the centrifugal inertia force of imbalanced weight on the vibration exciter can make the screen box to vibrate. Changing the eccentric weight of vibration exciter can get different amplitude.

.jpg)

.jpg)

.jpg)

.jpg)

This kind of inertia vibrating screen is also called single-shaft vibrating screen. It has two support forms: suspension support and pedestal support. In suspension support, the screen surface is fixed on the screen box and the screen box is suspended or supported by the spring. The bearing of spindle is installed on the screen box, and the spindle rotates in a high speed when driven by the belt wheel. The disk with eccentric weight is installed on the spindle, and it rotates following the rotating spindle and produces centrifugal inertia force, which can make free vibrating box to vibrate in an approximate circular trajectory.

1. High screening efficiency and high productivity.

2. Simple structure and easy to disassemble and replace;

3. Less electric power consumption .

The circular vibrating screen can be started only when there are no materials on the screen surface. Feed materials only after the machine operating steadily. When the vibrating screen works, workers should frequently observe the operating condition of the machine. If there is abnormal movement or unusual sound, workers should shutdown the machine timely, check and discover the reason, and then remedy the trouble.

| Model | Sieve layer |

Sieve area (m²) |

Mesh size (mm) |

Max. feeding size (mm) |

>Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double amplitude (mm) |

Motor power (kw) |

Sieve obliquity (°) |

Sieve specification (mm) |

>Dimensions (L×W×H) (mm) |

| 2YK1225 | 2 | 6 | 4-50 | 200 | 8-60 | 800-970 | 8 | 6P 5.5KW | 20 | 1200×2500 | 2930×1860×870 |

| 3YK1225 | 3 | 9 | 4-50 | 200 | 10-70 | 800-970 | 8 | 6P 5.5KW | 20 | 1200×2500 | 3070×1860×1210 |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3000 | 3430×1860×870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3000 | 3570×1860×1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3700 | 4050×1860×870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 800-970 | 8 | 6P 7.5KW | 20 | 1200×3700 | 4270×1860×1210 |

| 2YK1535 | 2 | 10.5 | 5-50 | 200 | 20-125 | 800-970 | 8 | 6P 11KW | 20 | 1500×3500 | 4120×2210×1230 |

| 3YK1535 | 3 | 15.75 | 5-50 | 200 | 21-125 | 800-970 | 8 | 6P 11KW | 20 | 1500×3500 | 4360×2210×1610 |

| 2YK1545 | 2 | 13.5 | 5-50 | 200 | 22-150 | 800-970 | 8 | 6P 11KW | 20 | 1500×4500 | 5120×2210×1230 |

| 3YK1545 | 3 | 20.25 | 5-50 | 200 | 22-150 | 800-970 | 8 | 6P 15KW | 20 | 1500×4500 | 5360×2210×1610 |

| 4YK1545 | 4 | 27 | 5-50 | 200 | 22-155 | 800-970 | 8 | 6P 15KW | 20 | 1500×4500 | 5930×2210×2060 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 800-970 | 8 | 6P 11KW | 20 | 1500×4800 | 5420×2210×1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 800-970 | 11 | 6P 15KW | 20 | 1500×4800 | 5660×2210×1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 800-970 | 8 | 6P 18.5KW | 20 | 1500×4800 | 6230×2210×2060 |

| 2YK1848 | 2 | 17.28 | 5-80 | 200 | 25-206 | 750 | 8 | 6P 18.5KW | 20 | 1800×4800 | 5420×2550×1420 |

| 3YK1848 | 3 | 25.92 | 5-80 | 200 | 32-276 | 750 | 8 | 6P 18.5KW | 20 | 1800×4800 | 5660×2550×1780 |

| 4YK1848 | 4 | 34.56 | 5-80 | 200 | 32-285 | 750 | 8 | 6P 22KW | 20 | 1800×4800 | 6290×2550×2160 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 5960×2550×1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 6260×2550×1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 800-970 | 8 | 6P 22KW | 20 | 1800×5400 | 6830×2550×2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 8 | 6P 30KW | 20 | 2100×6000 | 6720×2840×1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 8 | 6P 30KW | 20 | 2100×6000 | 7030×2840×1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 8 | 6P 37KW | 20 | 2100×6000 | 7300×2840×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 8 | 6P 30KW | 20 | 2400×6000 | 7020×3140×1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 8 | 6P 37KW | 20 | 2400×6000 | 7300×3140×1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 8 | 6P 45KW | 20 | 2400×6000 | 7600×3140×2380 |

| 2YK2870 | 2 | 39.2 | 5-100 | 200 | 120-680 | 750 | 8 | 8P 22×2KW | 20 | 2800×7000 | 7600×4320×1620 |

| 3YK2870 | 3 | 58.8 | 5-100 | 200 | 180-720 | 750 | 8 | 8P 22×2KW | 20 | 2800×7000 | 7800×4320×2120 |

| 2YK3072 | 2 | 43.2 | 5-100 | 200 | 200-700 | 750 | 8 | 8P 22×2KW | 20 | 3000×7200 | 7800×4520×1750 |

| 3YK3072 | 3 | 64.8 | 5-100 | 200 | 230-800 | 750 | 8 | 8P 22×2KW | 20 | 3000×7200 | 8000×4520×2300 |

| Model | Max. feeding size (mm) |

Processing capacity (m³/h) |

| 2YK1225 | 200 | 8-60 |

| 3YK1225 | 200 | 10-70 |

| 2YK1230 | 200 | 12-78 |

| 3YK1230 | 200 | 13-80 |

| 2YK1237 | 200 | 15-86 |

| 3YK1237 | 200 | 16-90 |

| 2YK1535 | 200 | 20-125 |

| 3YK1535 | 200 | 21-125 |

| 2YK1545 | 200 | 22-150 |

| 3YK1545 | 200 | 22-150 |

| 4YK1545 | 200 | 22-155 |

| 2YK1548 | 200 | 22.5-162 |

| 3YK1548 | 200 | 22.5-162 |

| 4YK1548 | 200 | 22.5-162 |

| 2YK1848 | 200 | 25-206 |

| 3YK1848 | 200 | 32-276 |

| 4YK1848 | 200 | 32-285 |

| 2YK1854 | 200 | 32-312 |

| 3YK1854 | 200 | 32-312 |

| 4YK1854 | 200 | 32-336 |

| 2YK2160 | 200 | 50-475 |

| 3YK2160 | 200 | 50-475 |

| 4YK2160 | 200 | 50-497 |

| 2YK2460 | 200 | 65-550 |

| 3YK2460 | 200 | 70-620 |

| 4YK2460 | 200 | 80-680 |

| 2YK2870 | 200 | 120-680 |

| 3YK2870 | 200 | 180-720 |

| 2YK3072 | 200 | 200-700 |

| 3YK3072 | 200 | 230-800 |