Magnetic Separator

Production Capacity:1–220 t/h

Feeding size: 3–0 mm

Shell diameter: 600–1500 mm

Applied material: magnetite, pyrrhotite, calcined ore, ilmenite, etc

Production Capacity:1–220 t/h

Feeding size: 3–0 mm

Shell diameter: 600–1500 mm

Applied material: magnetite, pyrrhotite, calcined ore, ilmenite, etc

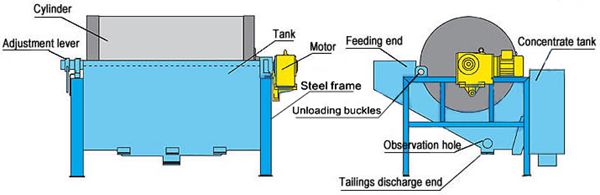

China Magnetic separator machine is one of the most universal machines for construction industry. It is also called magnetic drum separator which is used for getting iron containing in the powder. China magnetic separator is widely used for resources recycling in wooden materials, mining industry, kiln, chemistry and food, etc. Magnetic separator machine is applied to dry or wet magnetic separation of materials with particle size under 3mm, such as magnetic iron ore, magnetic pyrite mine, baking and titanium iron, coal, nonmetal ore and construction materials.

There are a variety of China magnetic separators that can be sorted into disk dry magnetic separator, flat ring magnetic separator, SHP wet magnetic separator and vertical wet magnetic sepatator.

Compared with the wet magnetic separator, this disk dry magnetic separator is the main ore dressing equipment most commonly used for iron ore separation and manganese ore sepatation. Dry magnetic drum separator can be sorted into one tubular and three rollers dry machine, two tubulars and two rollers magnetic separator. The magnetic induction can reached 880-1440 thousand Ann/m. Among them, the double-disk type is more widely used. The main body of this magnetic drum separator is composed of electronic magnetic iron and rotatable pendulum induction disk, and they presents a "W" shape. We can adjust the polar distance between disk and the electromagnets (the adjusting range can be 0-20 mm) through handwheel.

Plat ring magnetic sepatator adopts ring chain to form a closed circulation, copper tube of coil to form a low voltage, and cold water to calm down tempreture. Plat ring magnetic separator is composed of feeding device, concentrate ore and medium ore rinse device. The magnetic department consists of concentric rings both inside and outside magnetic body, and the spindle is located in the center of the closed magnetic circuit.

| Model | Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

| Model | Feeding size (mm) |

Processing capacity (t/h) |

| CTB6012 | 2-0 | 10-20 |

| CTB6018 | 2-0 | 15-30 |

| CTB7518 | 2-0 | 20-45 |

| CTB9018 | 3-0 | 40-60 |

| CTB9021 | 3-0 | 45-60 |

| CTB9024 | 3-0 | 45-70 |

| CTB1018 | 3-0 | 50-75 |

| CTB1021 | 3-0 | 50-100 |

| CTB1024 | 3-0 | 60-120 |

| CTB1218 | 3-0 | 80-140 |

| CTB1224 | 3-0 | 85-180 |

| CTB1230 | 3-0 | 100-180 |

| CTB1530 | 3-0 | 170-280 |