Unstructured Grid Works for Cement Rotary Kiln

Cement makes limestone and clay as main crude materials, these materials through fine crushing and grinding to be made into raw material, and then be fed in the cement kiln and calcined into mature material, by adding a moderate amount of gypsum to be made into cement after fine grinding.

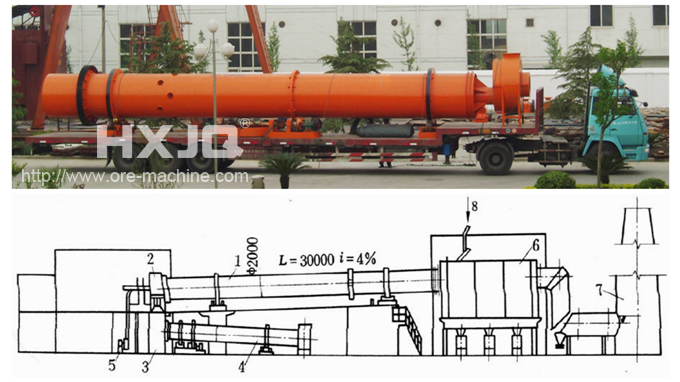

Cement is calcined in the cement kiln, and cement kiln can be divided into vertical kiln and rotary kiln , between which,vertical kiln has been eliminated now. Rotary kiln consists of kiln body, support device, block roller bearing device, transmission device, moving kiln head, sealing device, burning device and other parts.

In recent years, the unstructured grid is widely applied in the measurement of cement rotary kiln and gets rapid development; it fundamentally eliminates the limited effect caused by grid nodes; because nodes as well as the composition of unit are casual, so you can better deal with boundary problem; unstructured grid is formed due to the optimization of cement rotary kiln, thus the grid has high quality, flexible and diversified distribution and convenient control.

The unstructured grid that applies in the actual production of cement rotary kiln is composed by arbitrary triangular or tetrahedral grid, under normal circumstances, this kind of structure model is also referred to as a hybrid grid; when it comes the wide application to cement rotary kiln production, we can put it to the measurement ability, irregular change, good flexibility and practical applicability.

But after long actual operation and test on cement rotary kiln, we also find some shortcomings, that is the arrangement of grid is not very regular, requiring to set up the corresponding data structure to detect the relationship between the cells, then we should better control the grid spacing and shape so that it can reduce a corresponding working part .