The Lubrication Ways for Ball Mill

The main bearings of ball mill must be equipped with reliable lubrication device in working process. Large ball mill mainly adopts oil pump to take forced circulation lubrication; lubrication ways include hydrodynamic pressure way and static and dynamic pressure way.

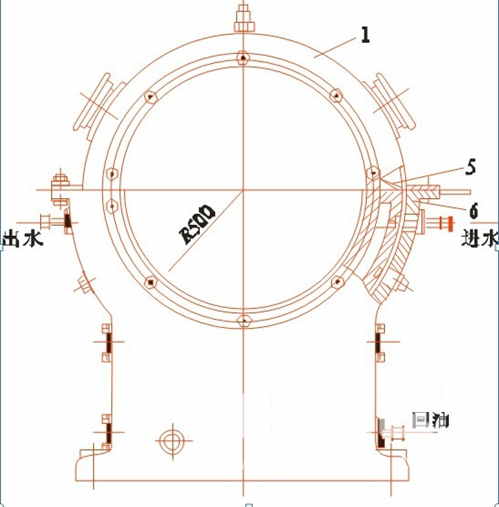

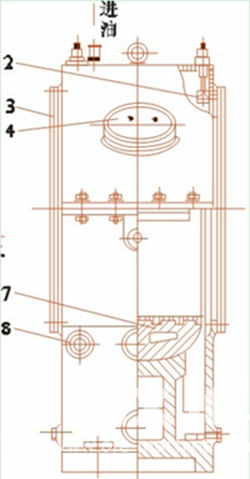

The hydrodynamic lubrication can be divided into oil pump feeding and oil ring feeding forms. Oil pumps feeding can be shown as following:

Main components of the ball mill bearing: 1 - bearing cap; 2- oil scraper plate; 3 - platen; 4 - inspection port; 5 - thermometer; 6 – bearing base; 7 - spherical watts; 8 - oil level hole

Lubricating oil enters into the bearing from oil pipe and injects into the hollow shaft, and then falls into the pad; the lubricating oil within the bearing housing reflows from the oil return pipe, go through filtering and cooling device to form closed loop fuel supply system. Due to the low running speed, the oil film formed by hydrodynamic lubrication is too thin to reach the liquid friction lubrication; it is equipped with spare oil ring so that keep the machine working reliably. Small and medium-sized ball mill often adopt oil ring feeding lubrication, the oil is brought by the oil ring, going though oil scraper bar to spill the oil on the surface of hollow shaft and bearing liner; the lubrication cooling effect is somewhat less than the fuel supply system, and the oil cannot be filtrated, but the structure is simple.